ABOUT US

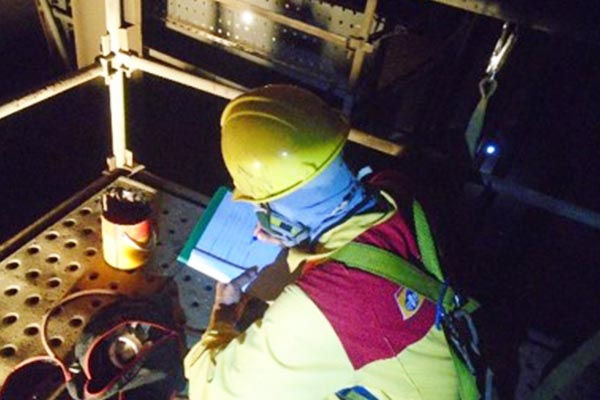

Subic Pnoy Marine Services Inc., ( SubicPnoy ) is a leading service provider of surface preparation and coating application with a primary mission of becoming the best in the Philippines when it comes to corrosion control. Its core competencies include internal tank coating and vacuum blasting.

It is the major service provider at Keppel Subic Shipyard engaged in cargo hold, internal tank upgrading, building and repair of ships and other specialized marine platforms. Responding to the requirements set by International Maritime Organization in upgrading ballast tanks of ocean going vessels, Subic Pnoy has the latest equipment to carry out and finish complicated internal tank coatings on budget, on schedule and most especially no lost time incident.

At present Subic Pnoy is one of the elite organizations that have the latest equipment for surface preparation. It has sixty (60) –nozzles surface preparation capacity, vacuum recovery machines that can be equipped with blasting vacuum nozzles, dehumidifiers ranging from 12,000cmh – 18,000 cmh, twenty (20) portable engine driven air compressors ranging from 950 cfm – 1,050 cfm, airless spray units, and pressure washing units with a working pressure of 300 – 500 bars. Skilled and experienced blasting and painting project personnel complement these equipment.

With the use of powerful and reliable dehumidifiers / airdrier Subic Pnoy is able to carry out complicated internal tank coating projects. Through dehumidifiers, humidity inside the tanks which are subjected to environmental factors are controlled. Proper dehumidification is required to prevent the presence of high humidity that causes rust bloom on the metal surface and consequently would lead to blistering and delamination. It also prevents condensation which may cause premature coating failures. Specifically, proper dehumidification system is needed to ensure that:

-

The required air humidity by Coating Manufacturers is maintained to lengthen coating life.

-

Condensation, flash rust and delamination are prevented by maintaining air dew point at three degrees Celsius.

-

Coating is completed thru one time painting and within schedule by extending environmental conditions conducive for coating.

Some of the successful high end surface preparation and coating application projects carried out are Global Sta Fe, ENSCO, Floatel, QGP, Maersk and Bras Siete oilrig pontoons and Shell Malampaya Project MP3.

Subic Pnoy shall continue to expand to maintain its status as an elite player in the surface preparation industry by continuing improve its work process, equipment and its skilled personnel.